MEET YOUR MATCH

THE LABORSAVETM MODELS

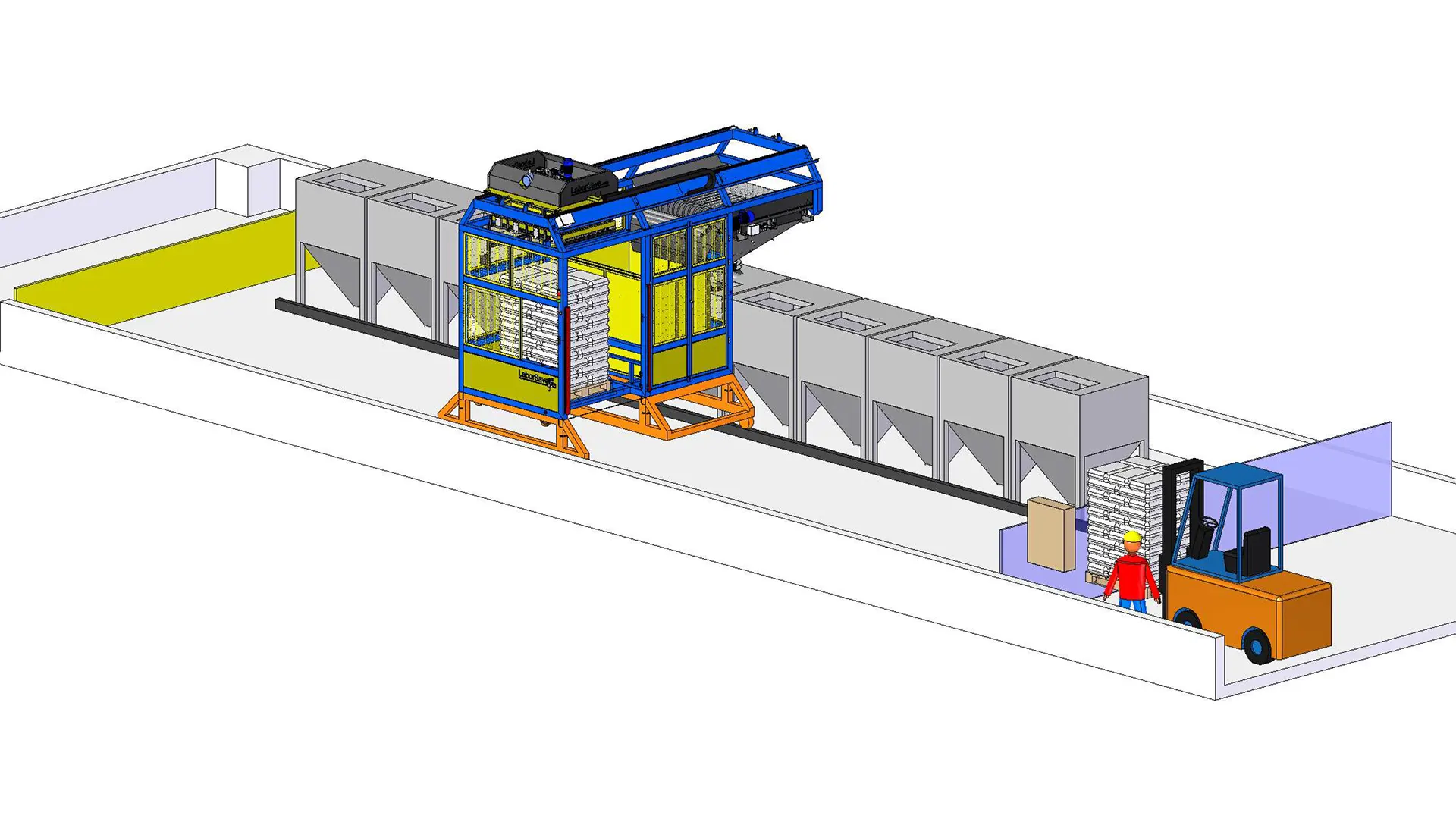

The LaborSaveTM system is available in several throughput-based models, offering 400 to 1300 sack/hour processing capacities, regardless of sack type, weight and arrangement on pallet, with more than 99.99% emptying efficiency.

Multiple pallet and multiple discharge station solutions are also available, enabling optimal use of manpower and production floor space.

LABORSAVETM HCL

With a maximum throughput of 400 sack/hour or 10 tons/hour, the compact LaborSaveTM HC-L model is ideal for small factories with a tight budget.

Capacity: 400 sack/hour I 10 ton/hour*

Emptying rate: More than 99.99%

Air consumption: 7800 L/hr

Air pressure: 6 bar, 99% dry

LABORSAVETM HC

LaborSaveTM HC was the first model introduced to market, offering throughput of up to 600 sack/hour or 15 tons/hour.

Capacity: 600 sack/hour I 15 ton/hour*

Emptying rate: More than 99.99%

Air consumption: 8100 L/hr

Air pressure: 6 bar, 99% dry

* Based on 125Kg per layer; Up to 250Kg load per layer

LABORSAVETM G2

LaborSaveTM G2 features an enhanced motion system and content discharge efficiency of up to 800 sack/hour or 20 tons/hour.

Capacity: 800 sack/hour I 20 ton/hour*

Emptying rate: More than 99.99%n 99.99%

Air consumption: 8600 L/hr

Air pressure: 6 bar, 99% dry

* Based on 125Kg per layer; Up to 250Kg load per layer

LABORSAVETM VHC

LaborSaveTM VHC offers superior processing capacity, most suitable for logistics companies, of up to 1300 sack/hour or 32 tons/hour.

Emptying rate: More than 99.99%

Air consumption: 8700 L/hr

Air pressure: 6 bar, 99% dry

* Based on 125Kg per layer; Up to 250Kg load per layer

LABORSAVETM MP

The system presents capabilities of automatically and concurrently opening and emptying up to 10 separate pallets carrying different raw materials and discharging the various sack contents into a single hopper, using an automatic cleaning system in between one material type discharge and the next, and a built-in stacker for the empty pallets.

Emptying rate: More than 99.99%

Air consumption: 2000-3000 L/hr

Air pressure: 6 bar, 99% dry

* Based on 125Kg per layer; Subject to number of discharge stations; Up to 250Kg load per layer

LABORSAVETM MS

The system presents capabilities of automatically and concurrently opening and emptying of up to 10 different raw materials and discharging the various sack contents into multiple feed hoppers, using an automatic cleaning system in between one material type discharge and the next, and a built-in stacker for the empty pallets.

Emptying rate: More than 99.99%

Air consumption: 2000-3000 L/hr

Air pressure: 6 bar, 99% dry

* Net for each pallet; Based on 125Kg per layer; Subject to number of discharge stations; Up to 250Kg load per layer

SEAMLESS SIMPLICITY

How It Works

LaborSave is the world’s first and most efficient raw material handling solution.

The patented, fully automated robotic system is loaded with a full pallet of raw material sacks via forklift or conveyor belt.Mechanical claspers are used to pick up the top layer of sacks and carry them over a set of specially designed cutting blades, which cleanly cut open the sacks without producing sack shavings. The cut sacks are then shaken above the feed hopper and efficiently discharge the sack contents with an outstanding success emptying rate of more than 99.99%. The empty bags are ejected into the integrated empty sack compression chamber for disposal.

Once the last layer of sacks has been loaded, the empty pallet is removed from the system and a new full pallet is automatically loaded.

PURPOSE-BUILT

Customization possibilities

The LaborSaveTM models can be configured and customized to meet specific and changing operational needs:

Elevated Efficiency

LaborSave Peripheral Equipment

The highly modular LaborSaveTM system models can be accessorized with complementary peripheral equipment, which increase the efficiency of the sack emptying workstation even further. Add-on features, available during system installation and commissioning or later, augment functionality in accordance with specific customer needs and requirements.

Integrated empty bag compression

A built-in feature with all LaborSaveTM standard models, the compression bin can compress and store up to 2,000 empty bags.

Full pallet feeding conveyor

An automatic conveyor belt, pre-loaded with up to 4 full pallets, syncs in real-time with the LaborSaveTM system to streamline the automatic loading of full pallets into system with perfect timing and zero downtime, while allowing freeing forklift operators to handle other tasks before having to reload the conveyor with new full pallets.

Automatic cleaning system

Empty pallet removal conveyor and stacker

A synchronized conveyor belt removes empty pallets from the system and automatically stacks 20 pallets on average, regardless of pallet dimensions, reducing even further the possibility of machine or operators’ downtime.

Aspiration unit

The pros and pros

Advantages

The highly durable and robust LaborSaveTM system offers maximum efficiency in minimum floor space, is easy to install and operate and comes with a lifetime warranty.

Increased capacity, improved workflow efficiency and greater operational flexibility, eliminated contamination risk, better use of raw materials, greater work safety and cleaner work environment, and significant saving on material loss and labor, translate into a typical ROI of less than 6 months.